The gyroscope is a kind of instrument to accurately determine the range of movement of the object, it is a modern aviation, navigation, inertial navigation instruments are widely used in aerospace and defense industry, the development of industry of a country, national defense and other high-tech development has a very important strategic significance.

High precision gyro is widely used in aircraft, ships, submarines and missile navigation and guidance, satellite, spacecraft terrain tracking matching and guidance, rocket launch tracking and measurement, and other fields.

The gyro motor is the core component of the gyroscope. Its operating stability directly affects the directional performance of the gyroscope. The operation stability of the gyro motor is reflected in the change of the output mechanical characteristics, and the change of the output mechanical characteristics will be reflected in various forms in the input electrical parameters. Therefore, the input voltage, current and instantaneous power are analyzed, and the variation law of the input parameters, especially the input power, is helpful to understand the performance of the motor.

According to the characteristics of different users and solve application tailored scheme, AnyWay custom "gyro motor production line test, gyro motor research test, gyroscope motor aging test to solve the" three sets of system solutions, and has application in the aerospace, Beijing Qingyun innovation and technology etc..

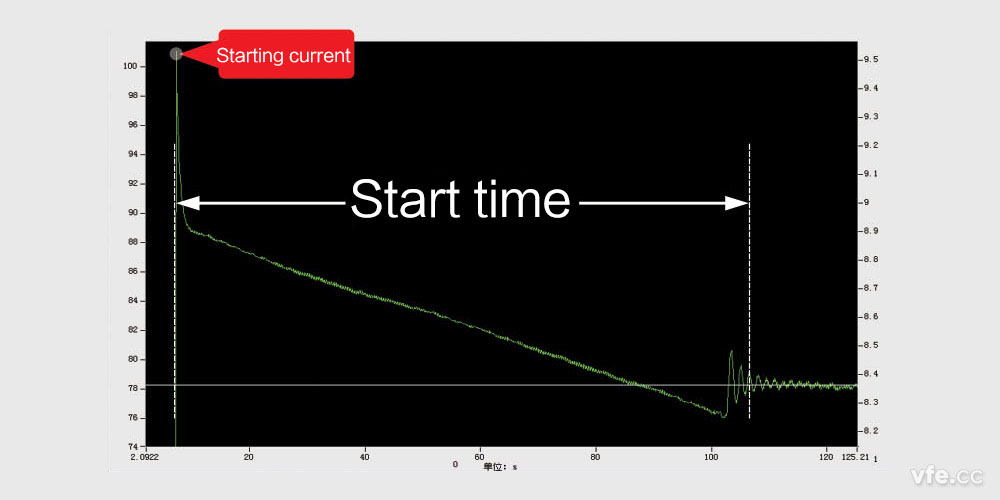

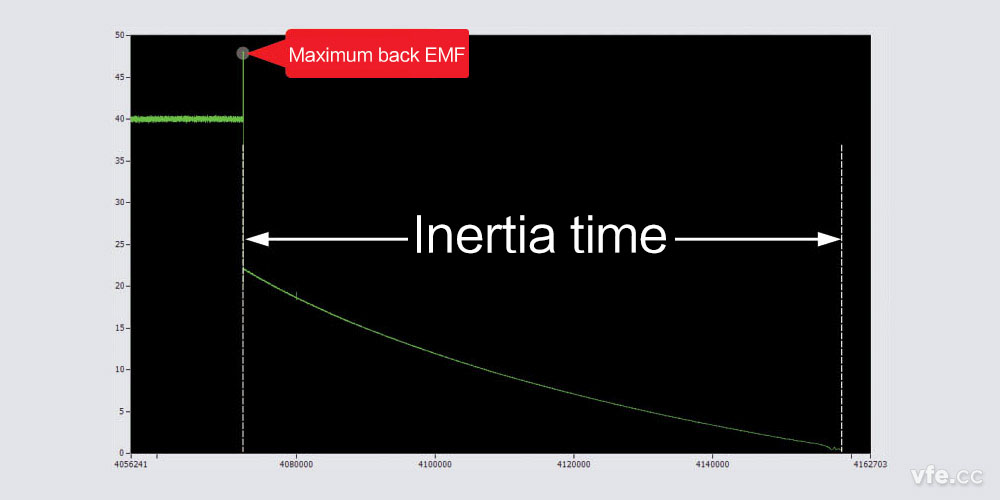

The test program focuses on the gyro motor input power and stability analysis of the jitter can be measured at the same time, 9 sets of gyro motor, automatic for each motor's start time, the inertia time, starting current, starting current, power stability and power stability are fast, high efficiency, reliable test.

Testing scheme of gyro motor and power line

This scheme is designed for scientific research, focusing on the test and analysis of gyro motor and power supply.

Power supply test: test the voltage regulation of the power supply. The harmonic and three-phase unbalance of the power supply can be adjusted, and the influence of the power supply on the motor performance can be studied. And then put forward the work of the power supply of the performance indicators of the accurate requirements.

Motor test: can comprehensive test the motor start time, the inertia time, starting current, starting power, voltage harmonics, harmonic current and instantaneous power harmonic, can be more comprehensive understanding of the mechanical characteristics of the motor, and the stability of the motor for quantitative analysis.

Gyro motor and power research and test program

This scheme focuses on the analysis of the original data of the gyro motor, and provides the complete data record in the life cycle. Through the analysis of the original data record and the big data analysis, the product specificity is studied and the improvement direction of the product is clear.

Gyro motor aging test scheme

The starting time can be calculated by starting the curve by recording the RMS value of the starting current.

The power value of each cycle of the starting process is recorded, and the starting power curve is described.

The amplitude and frequency of the back EMF of the motor in the process of the idle rotation are detected. When the amplitude and frequency are close to zero, the motor is stopped to rotate.

The voltage and current harmonic analysis, voltage and current in no harmonic current or excessive harmonics, which is caused by the nonlinear characteristics of the motor, should control the harmonics through design and process.

The change of mechanical vibration on behalf of motor output power, while the output power changes will inevitably lead to large changes in input power, the harmonic analysis of instantaneous power, help us to understand the mechanical characteristics of motor, mechanical parts and can be easily diagnosed by using the characteristics of motor fault.

The instantaneous current and instantaneous power of the gyro motor contains a large amount of valuable information in the original data (waveform data). The conventional instrument can only measure the average value of these quantities within a certain period of time, the average missing a large number of data can reflect the characteristics of the motor. The imported high-precision electrical parameters testing instrument, basically do not provide the original data, is not conducive to the comprehensive testing and understanding of the characteristics of the motor.

Based on the analysis of the original data of the same kind of fault motor, it is found that the common characteristics and the corresponding relationship between the data characteristics and the fault type can greatly improve the work efficiency of the quality inspection department.

Through the analysis of a large amount of data of different batches of similar motor or using different manufacturing process, the performance differences between the master of the micro motor, to provide effective data support for improving the production process or research work. To lay a scientific foundation for the development of higher performance gyro motor.

Related articles

Popular articles