Guizhou Aerospace Linquan Motor Co., Ltd. is affiliated to the Tenth Research Institute of China Aerospace Science and Industry Corporation. It is a professional research and production unit of aerospace micro motor, servo drive control, secondary power supply and miniaturized telemetry equipment in China. It is a modern aerospace military industry enterprise integrating R & D and production, integrating military and civilian integration, cross regional industrial layout, and products facing domestic and foreign markets.

The electric vehicle wheel motor test system is mainly used to collect the wheel motor controller, wheel motor input and output electrical parameters and mechanical parameters of the wheel motor test bench, share the data to the test bench software, and complete the new energy assessment test of the tested motor controller and wheel motor.

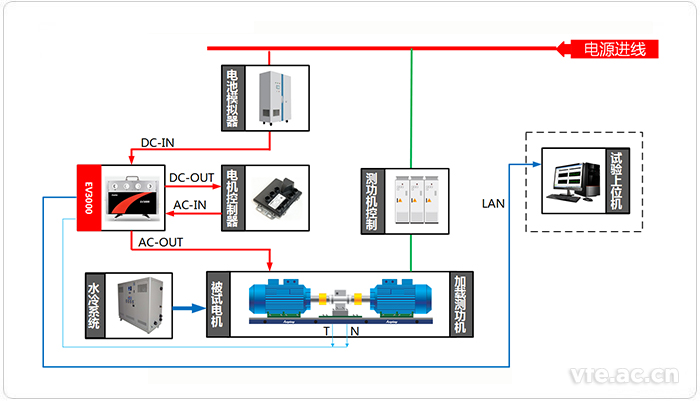

Dc-in: the DC output of the battery simulator is connected; DC-out: DC input of the controller under test; Ac-in: controller AC output; Ac-out: AC input of tested motor

Figure: application topology diagram of electric vehicle wheel motor test system

The application topology diagram of the electric vehicle wheel motor test system is shown in the above figure, which mainly includes battery simulator, motor under test controller, water cooling system, motor under test, load dynamometer, dynamometer controller, ev3000 power system comprehensive tester, torque and speed sensor, test upper computer, installation test platform and other equipment.

In this scheme, ev4000 power system comprehensive tester is selected to meet the testing requirements of electric vehicle wheel motor.

Ev4000 power system comprehensive tester is equipped with 1 DC test channel and 3 AC test channels, which can effectively meet the test of driver DC input 1000vp and 1000ap and AC output 1000vp and 1000ap.

Ev4000 is equipped with a torque and speed acquisition and measurement module, which supports ± 10V analog voltage input, 0 ~ 20mA / 4 ~ 20mA analog current input, pulse signal input with peak value below 20V / 400kHz and other signal modes. It is compatible with the current mainstream torque and speed sensors in the market.

Ev4000 adopts Ethernet communication, and the instrument is installed on the test site. All the test steady-state data and transient waveform data are shared to the test host computer through the Ethernet LAN port. The test host computer obtains the test data of all working conditions and completes the performance test of the tested driver and motor

| Measuring point | Equipment name/td> | model | quantity |

| DC input and three-phase AC output of motor controller | Power system comprehensive tester | EV4000 | 1 |

Related articles

Popular articles

Label