High speed rail is widely used in AC electric locomotive to realize electric traction. The core component of electric traction system is traction converter and AC asynchronous traction motor. The performance of traction converter and traction motor directly determines the performance and safety of high speed rail.

Traction system is an important feature of the power density is large, usually with low switching frequency (usually less than 1KHz) to reduce switching losses. Low frequency and high frequency characteristics are important indicators of the traction system, generally require accurate testing of the fundamental frequency range is wide, low frequency is lower than 1Hz, high frequency of up to 100Hz.

For low frequency signal, due to a longer period, the required AC sampling operation cycle is longer, and the output harmonic of traction converter with high frequency, sampling rate and higher requirements, so the need of related test equipment have large storage capacity and strong computing ability.

For high frequency, as an example as 800Hz switching frequency and 100 fundamental frequency, a PWM cycle contains only 8 pulses, the switch frequency and the fundamental frequency is close, causing serious waveform distortion, for synchronization synchronization source is a great challenge. And at this time, the average value of the calibration is far from the true fundamental value, and the power analyzer which is used to replace the fundamental value is not applicable.

Test equipment must achieve the needs of the development of high-speed railway, provide the original complete test data to the user, a record of the original data, two times through the late development of professional software can get more valuable information, and it can avoid a lot of repeated test.

WP4000 variable power analyzer using cutting version of kylin operating system embedded microprocessor with high performance and high efficiency, has the massive storage space and powerful computing capability, can achieve low frequency under high sampling rate test, all the original data records of the test process, it can fully reproduce the original data through the testing process, any parameters of any want to know the moment from the reconstruction process, fully achieve the above requirements.

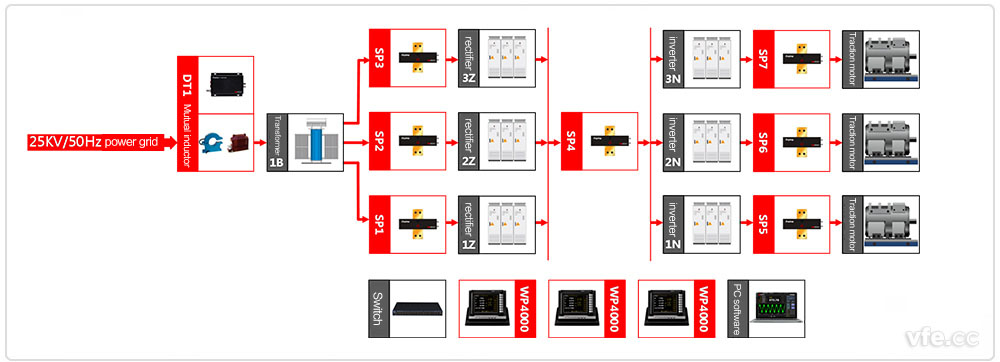

XEMC is a unit of deputy director of vice president of China City Rail Transportation Association units and China City Rail Transit Association Branch, the rail traffic AC traction laboratory transmission system is the first in the traction drive system test laboratory, can be on the subway, city rail transit traction motor, VVVF test, VVVF traction traction inverter the inverter and the motor of the electric drive system and auxiliary power supply (SIV) test.

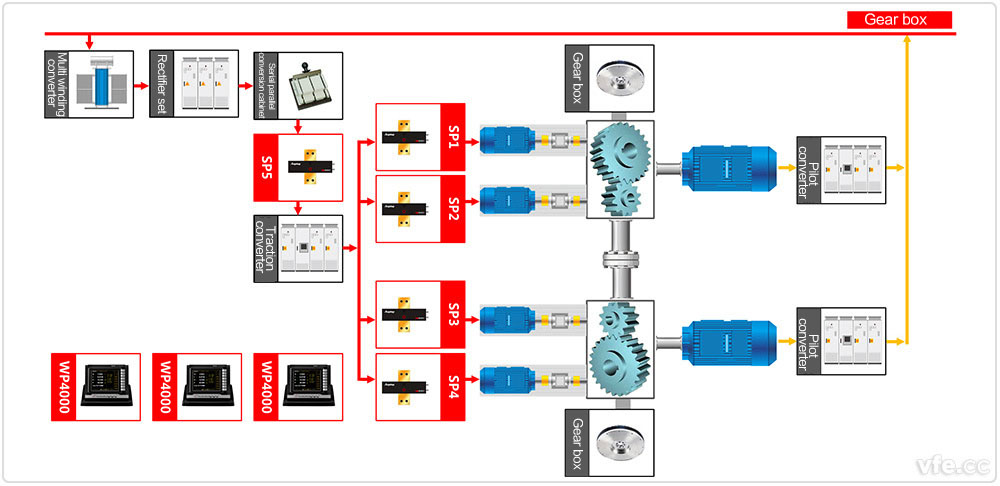

Test principle diagram of AC traction drive system

CRRC motor is a a core component of local supplier. The Ministry of Railways only a harmony type high-power electric locomotive and EMU motor, transformer two key components. The testing station has the technical ability to carry out the inspection service according to the international standards. The test data and test report issued by the test station will be recognized by the more than and 70 countries and regions such as the United States, Japan, India, etc.. From research and development to manufacturing, a full grasp of high-speed EMU, high-power locomotive traction system quality.

The traction motor testing system for traction motor testing research test, using the electric energy feedback structure, the tested motor electric operation, with drag motor power, with electric energy can be generated by motor with inverter feedback to drag the end, to provide energy for the drive inverter and the tested motor operation in the internal flow test bench to realize energy feedback, during the operation of the external power grid only need to add the energy loss, greatly saving the operation cost.

Schematic diagram of traction motor test bed

CRRC Locomotive Research Institute traction system laboratory is rail transportation equipment research and development of independent innovation platform of traction drive and control system, the electric locomotive traction play a crucial role in the test system, to promote China's high-speed rail technology from the introduction of digestion and absorption to innovation, to catch up from behind to achieve world-class level.

Schematic diagram of traction motor test bed

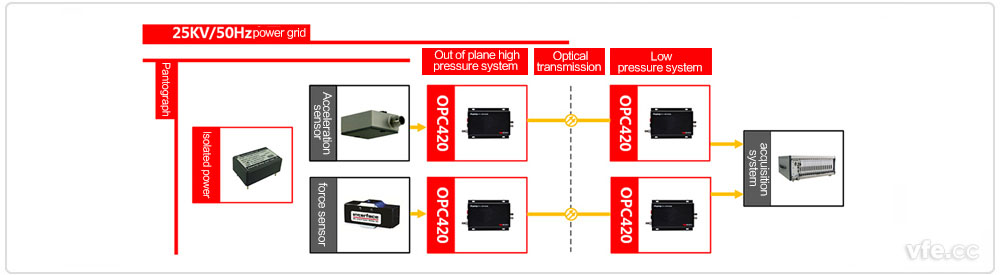

The pantograph of electric locomotive is operated in the high voltage AC environment, and it is easy to appear the phenomenon of arc pulling in the high-speed operation. The influence of the electromagnetic interference susceptible to analog output sensor transmission of the conventional process, lead to decrease the accuracy of measurement even can not work normally, and the front end connected by cables, easy to cause high pressure introduced, safety equipment and personnel under threat.

The YINHE ELECTRIC OPC series optical fiber converter converts the analog signal to digital signal, through the optical fiber transmission and then revert to the analog signal seamlessly compatible with the original system, electrical isolation, greatly enhance the power system electromagnetic compatibility testing bow online.

Schematic diagram of the testing system of pantograph

Related articles

Popular articles