OneSummary

The traditional way to measure the speed of the motor is generally used in the motor shaft end of the installation of photoelectric sensor, encoder to achieve, which applies to the motor shaft extension of the speed measurement of the exposed position. But the existing turbine submersible pump and submersible pump unit basically consists of motor, pump, protector and separator etc., no rotating parts exposed, so the photoelectric sensor and the encoder can not be installed, some users using vibration method to measure its speed, which adopts vibration tachometer measurement, import error is larger. And the price is not cheap, in the test system is sealed, set a better balance, using vibration method can not be tested.

For this, YINHE ELECTRIC Co. Ltd. carried out research on the new method of speed measurement of electric submersible pump unit adopts the induction method, and successfully developed the DM4022 induction type tachometer. After many experiments, the speed measurement accuracy of the new measurement system can reach 0.1%, the successful development of this system, as the speed of electric submersible pump set provides the most accurate and feasible method.

DM4022 induction tachometer

Design of DM4022 inductive tachometer for rotor asynchronous motor in rotating magnetic field by cutting magnetic lines induced current frequency is the rotor of the motor frequency and motor stator voltage frequency difference frequency. This difference frequency multiplied by 60 to get the difference of the asynchronous motor, the frequency of the power grid is multiplied by 60 to get the synchronous speed of the motor, by the synchronous speed minus the difference between the motor rotation speed.

The frequency of submersible pump unit as an example, the differential frequency inductive sensor is the rotor current frequency electric submersible pump motor, when the motor rotates, the rotor induced current generated by the rotor of the motor frequency is the frequency and frequency difference frequency motor stator voltage, 50Hz, multiplied by 60, by induction motor slip 3000r/min 50Hz, the grid frequency multiplied by 60 to get the motor synchronous speed, slip 3000r/min minus 3000r/min, get the speed of the motor 0r/min, showed that the submersible pump motor does not rotate.

TwoProduct features

1、Non-contact measurement. By adopting the principle of inductive measurement, the traditional method of measuring the speed of the photoelectric sensor is changed, and the problem that the rotating part of the motor is not exposed and the rotational speed can not be measured is solved;

2、Easy to install, easy to maintain. The user only needs the induction type speed sensor to be placed near the motor to be tested, and the measurement of the rotational speed can be carried out;

3、Front end digital technology. The measured signal is converted to digital signal at the sensor end, and is transmitted to the host computer through the RS485 or the optical fiber bus;

4、High measurement accuracy. The speed measurement accuracy is as high as 0.1%, far more than the measurement accuracy of users using galvanometer or vibration mode of speed measurement, allows users to grasp the running state of motor and pump more accurately;

5、Humanity computer software. The system set up after the success of the PC software, the user may want to analyze data in detail, including motor synchronous speed, rotational speed, pump speed, asynchronous real-time slip information;

OneProduct application

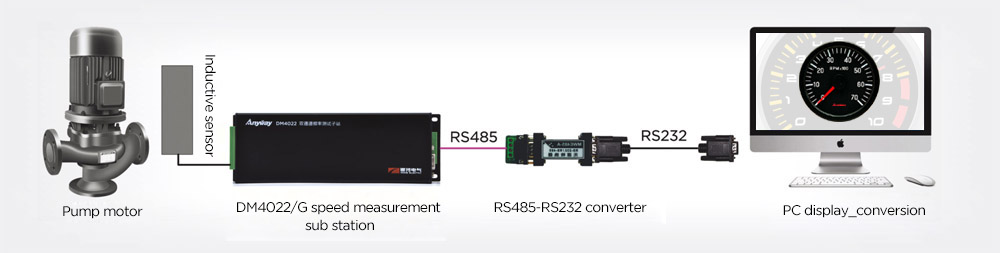

Widely used DM4022 inductive tachometer in pump and pump speed test, the pump speed to test for example, illustrate the application principle of DM4022 inductive tachometer and its application principle as shown below:

Application of DM4022 induction tachometer in water pump unit speed test

OneTechnical parameter

The main technical parameters of DM4022 induction tachometer are as follows:

◆ Bus transmission mode: RS485/ fiber

◆ Working power supply: AC220V, 50/60Hz

◆ PC data interface: RS232

◆ Stator frequency measurement range: 20Hz~100Hz

◆ Slip frequency measurement range: 0.1Hz~5Hz

◆ Frequency measurement accuracy: 0.1%

◆ Power consumption: less than 2W

◆ Operating temperature: 0 degrees C ~ 40